In this article, we will be

discussing how to develop element mathematical model from scratch using the direct method.

The development of an element mathematical model is a crucial task, and it

belongs to step # 2 of the procedure, requiring to perform 6 steps in total, for

solving problems using FEM. For further details on FEM procedure, see previous

articles on this topic.

When we are using a commercial FEM

software package, we choose an appropriate element type from the element

library of the software depending on the nature of our problem. Being end users, we

do not need to derive and implement the element mathematical model. We just need

to use these ready-made elements. However, using there elements without knowing how

they are developed, is not that interesting. Is not it?

Let assume that we may not have

access to costly commercial software packages, or sometimes we want to solve a

problem and there is no suitable element available in the element library of an open-source or commercial packages, then, what will we do? The answer is that we simply drive the element

mathematical model, implement it and solve our problem.

The development of element

mathematical modelling can be broadly done either by direct formulation method or

using formal approach. The direct method is based on intuition and is

suitable for solving simple problems. On the contrary, the formal approach

requires intensive involvement of mathematics and is suitable for complex

problems. Moreover, the formal approach is attributed to various methods like the

weighted residuals methods (e.g. Galerkin method etc.), and the variational

methods involving the calculus of variation and the minimization of potential

energy (e.g. the Rayleigh-Ritz method etc.).

Here we will be deriving the

mathematical model of 1D bar/spring element having 02 nodes and 1 dof per node,

using direct stiffness method. It should be kept in mind that for understanding

of FEM, the development of element mathematical model using direct formulation

is a good starting point.

Consider an axially loaded elastic bar

member as shown in Figure 1a. The governing differential equation for the bar

element is as following:

In case of FEM, we need to discretize

the continuous do

main of axially load bar structure member. The discretized

element having 2 nodes, where each node represent 1 nodal displacement dof,

subject to axial nodal forces, is shown in Figure 1b.

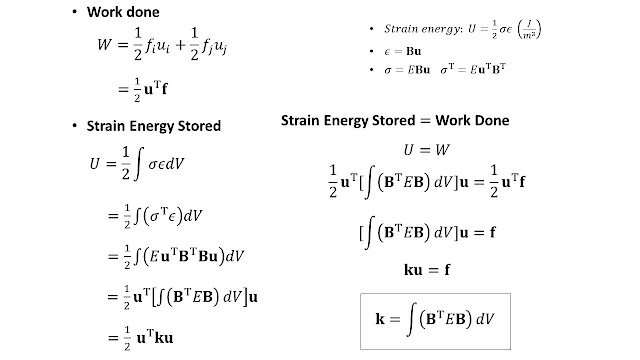

Let’s express continuous

displacement in terms of nodal displacements of discretized element. Applying

force equilibrium at each node, we can drive force equation, as shown below.

Finally, expressing the force equations in the matrix form, which is the

element stiffness matrix we are looking for. How simple force equation is.

The above element stiffness matrix will be assigned to the discretized domain, followed by the element assembly process and other steps involved in performing FEA to solve the problem.